Cost-Effective Embodied Carbon Reduction Through Structural Design Choices

January 21, 2025

Life Cycle Assessment and Costing Study – Cambie St

April 16, 2025

The carbon impact of the construction sector is large, with 11% of our nation’s emissions associated with materials and construction activitiesiii, As understanding and expectations around embodied carbon grow in the industry, life cycle assessments (LCA) have evolved from reflective accounting exercises to drivers of design. No longer is a model generated solely based on final drawings and generic intensities; carbon is now a design metric. Iterative models are informing the shape and composition of buildings, similar to how energy models are employed to reduce power consumption. Meaningful carbon reductions must be ingrained into the design concept, rather than “add-ons” at the end of design or in construction, which generally only offer marginal benefits and are costly to implement. Delivering the carbon-efficient buildings mandated by new legislation and certifications requires collaboration across all design and construction stakeholders.

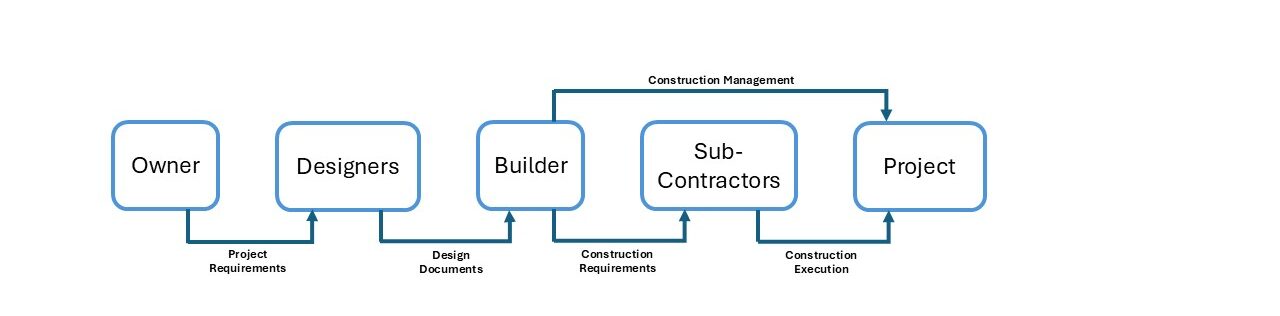

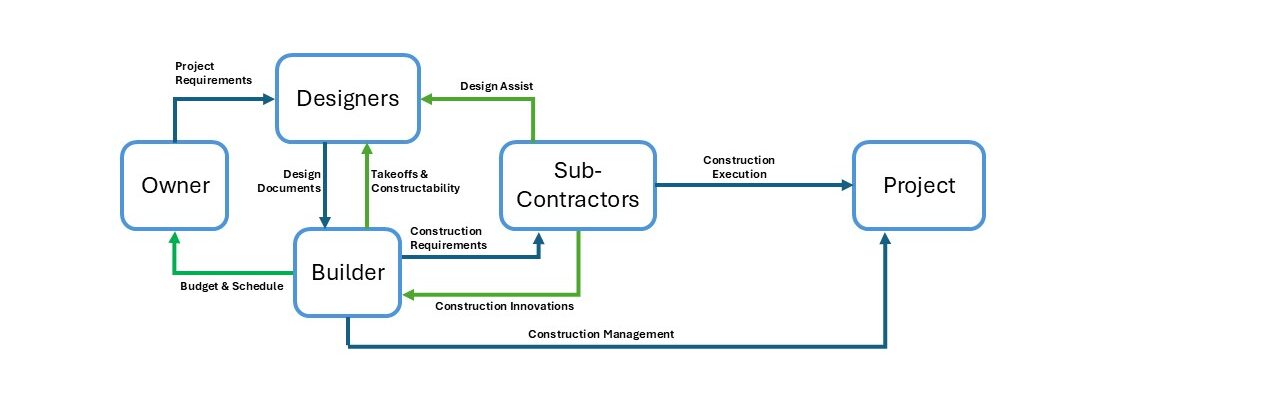

Involving the builder in early stages of design results in a greater impact on carbon reduction outcomes, as they can supply more reliable quantity takeoffs than a Building Information Modeling (BIM) export. Where models may be under-developed, the builder can provide critical insights on constructability and material availability, which tangibly impact the execution of the building construction. The builder can also analyze the cost impact of various sustainability design decisions, and the sustainability impact of cost-driven decisions. As such, contract models that encourage this up-front collaboration (as shown in Fig 1b) and feedback are preferred to linear lump-sum or time and material agreements (as shown in Fig 1a).

Fig 1a. Conventional Design-Bid-Build process

Fig 1b. Collaborative design and construction process

Early partnering with trades and suppliers is also helpful in ensuring availability of required materials (such as pre-ordering low-carbon options), and in confirming sustainability project requirements are understood. Carbon can be employed as a procurement metric to prioritize reductions and, when following best practice on communication and expectations, has shown a negligible impact on cost. There are ongoing hurdles in procuring low-carbon materials, largely around documentation availability and familiarity; however, these struggles have eased significantly in recent years as the market adapts. The following changes are still needed to bring low-carbon procurement to scale:

- specifications must be written with consistent, performance-based language

- documentation submittals during procurement must be streamlined to avoid rework

- standards/templates must be developed so that all owners and builders are requesting and evaluating the same information consistently.

This is already underway as the leading regulators, owners, designers, and builders work collaboratively to simplify and improve the process, helping to drive industry forward.

Policy and Leadership

As one of Canada’s largest builders, EllisDon understands the impact of our work, not just on our skylines, but also our carbon future. We recognize the importance of our role in driving positive change towards decarbonizing our industry and are committed to championing best practices. We are a founding and managing partner of the Climate Smart Buildings Alliance (CSBA), which recently launched the Responsible Builders’ Pact. This opt-in industry-wide pledge aims to reduce the emissions of buildings, with a focus on materials emissions. All 37 current signatories commit to prioritizing low-carbon options where possible and to report on progress, starting with ready-mix concrete.

Large shifts in the practices of any sector require buy-in from its members, and industry-led initiatives that support science-based net-zero targets such as CSBA, SE2050, and CLF are necessary to facilitate change. However, EllisDon strongly believes that clear and attainable regulation by authorities is a critical component of success. Regulating authorities like the Government of Canada, the City of Toronto, and the City of Vancouver have helped rapidly shift the national conversation around construction and building decarbonization due to their achievable and approachable policies. These “first movers” have established a common language and a set of expectations around carbon accounting and reduction success; this shared knowledge is helping building owners, designers, and trades across the country design and construct low carbon buildings. Additionally, mandatory policies create economies of scale, de-risking decarbonization for manufacturers and designers by generating demand and promoting competition for new solutions. Low-carbon options therefore become more plentiful and less costly to adopt.

Vancouver has been particularly successful in advancing decarbonization due to its smart use of progressive emission reduction and reporting requirements, giving the market ample time to adapt and the opportunity to provide feedback. Starting in 2017 with the launch of the embodied carbon rezoning requirements, the most high-profile projects in the city have been subject to more stringent sustainability outcomes, including the completion of a whole building LCA. This successful introduction was followed by the wide release of the “Embodied Carbon Guideline” for the Vancouver Building Bylaw in 2023, which introduced a reporting and threshold mandate to all Part 3 buildings. This document has been received as a critical piece of policy infrastructure and has been adapted into a federal public resource, the National Whole-building Life Cycle Assessment Practitioner’s Guide (2024), by the National Research Council (NRC) and Treasury Board Secretariat (TBS).

Reality Check: As-Designed vs As-Built Carbon

The change from simple, reflective carbon modelling to proactive modeling has been significant, enabling carbon-informed design decisions and the potential for greater emissions reductions – but do these results translate when moving from virtual to actual?

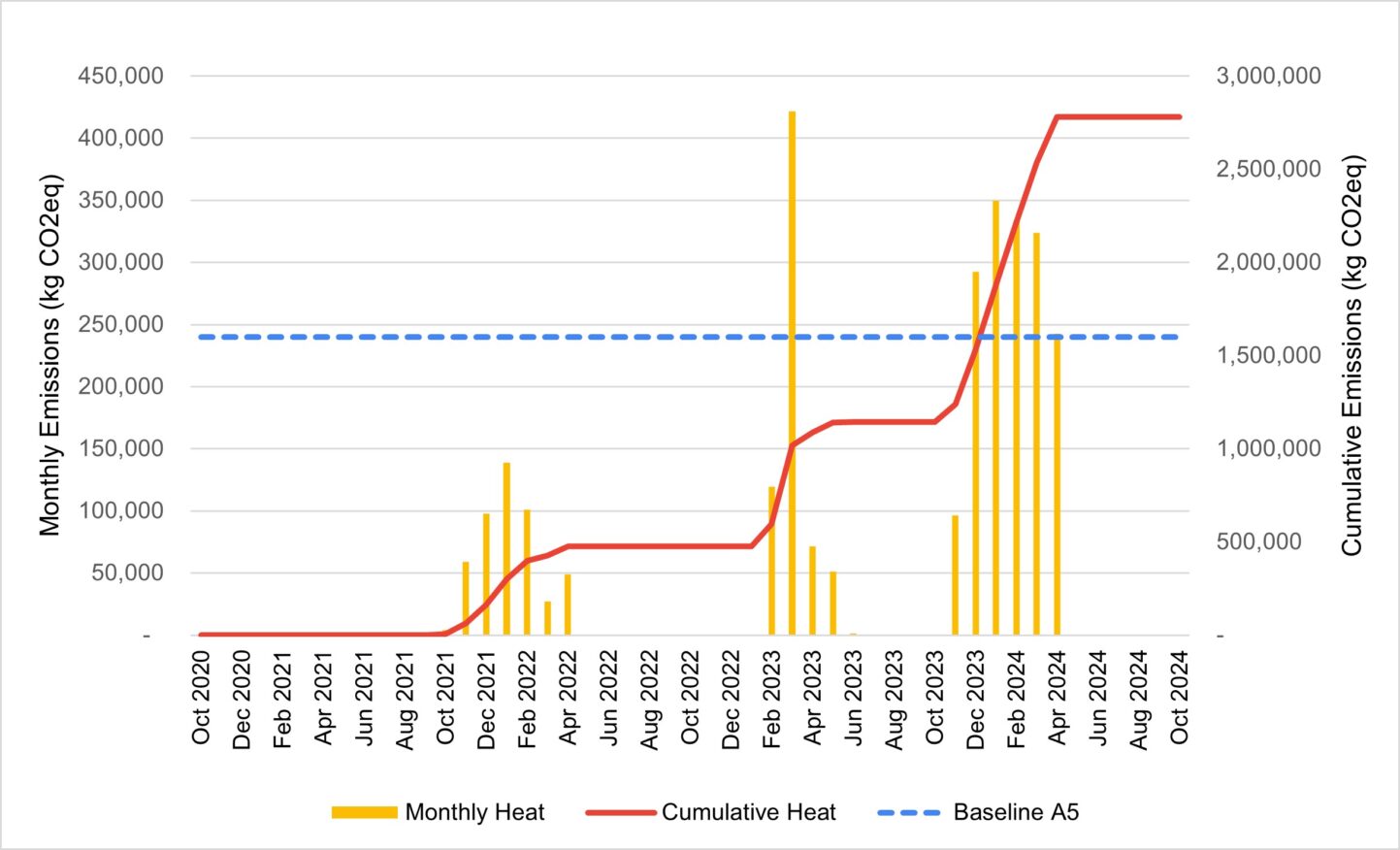

There is a large data gap in the industry on the impact of construction processes and decisions, and how material quantities and selections differ from design assumptions. EllisDon is running pilot projects across the country to better understand the scale of these emissions and their sources, and to identify solutions to mitigate them. Current software estimates assume <10% of a building’s whole-life embodied carbon is generated in the transport and construction phases; however, our analysis of a large project in the BC lower mainland indicates that this is a major underestimate. Canadian construction spans the full calendar year; our findings show that space heating alone over the three years of the project nearly doubled the entire A5 carbon budget per the design LCA.

In addition to tracking the emissions generated by our site and construction activities, we are working to reconcile the as-delivered material quantities and carbon intensities with those assumed in the LCA. We are starting by targeting high-carbon and easily documentable materials on select projects. This means capturing the tonnages of metal products (rebar, structural steel) as well as mix-by-mix poured concrete. This information is then used to supersede the information in the design LCA. This approach is being implemented on the City of Vancouver’s Amphitheatre project at the Pacific National Exhibition (PNE), profiled below, which has recently started construction. Actual carbon accounting on projects with supportive ownership and design teams is significantly easier, and EllisDon supports any regulatory moves to incentivize this tracking.

To bring the tracking to scale, we must streamline our practices and processes to efficiently gather this information. EllisDon is trialling software solutions to automatically collect site transportation and equipment usage data. When we and our partners implement low-carbon alternatives, like electrified temporary heating, electric delivery vehicles, and battery-solar hybrid generators, we need to fully understand their impacts, reward successes, and be able to share the information with all relevant parties.

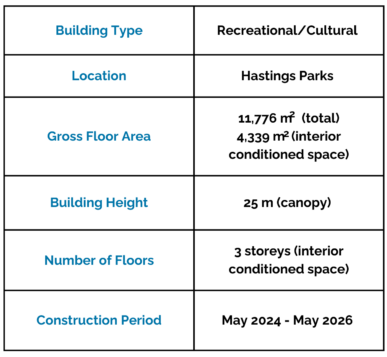

Project Spotlight: Freedom Mobile Arch

As part of the redevelopment of Vancouver’s historic Hastings Park, the new Amphitheatre will be located adjacent to the Pacific National Exhibition’s Fairgrounds, with an expansive vista of the North Shore mountains. The Amphitheatre will host 10,000 spectators and provide a much needed year-round, open-air entertainment venue to the city and surroundings. Central to the design of the venue is its massive free-span timber and steel arched canopy, complemented by curving concrete hardscaping and seating. As a City of Vancouver project, the Amphitheatre has been designed to not only contribute positively to the community but also the climate, in line with the City’s commitment to sustainability. The project is pursuing LEED Gold and Zero Carbon Standard – Design certifications and has a target to reduce embodied emissions by 40% from a conventional equivalent baseline.

Fig 3. Freedom Mobile Arch canopy (rendering by Mir)

Project Overview

Project Team

To reach the City of Vancouver’s ambitious corporate carbon reduction goals, both for operational and embodied carbon, requires all project stakeholders to be aligned on sustainability goals from conception. It is not possible to rely solely on finding “efficiencies” along design and procurement, such carbon-conscious designs must be created through cross-disciplinary collaboration and willingness to consider alternative solutions. Highlighted below are three major design and procurement decisions that are contributing to the Amphitheatre’s reduction in embodied carbon, which is on-track* to meet the City’s leadership sustainability goals.

Mass Timber:

Labour Effort: High, Carbon Impact: Significant, Cost: Increase

Rather than a canopy consisting solely of various metals, timber has been added to the structural design to reduce carbon and for architectural beauty. Of course, mass timber structures still rely heavily on more traditional components, steel connections between and around the timber members are significant, but reduced compared to a conventional design. To ensure the success of the mass timber implementation it is critical that the design team work closely with the structural manufacturers through a design-assist framework. EllisDon awarded the scope to Walters for structural steel and Nordic Structures for mass timber and conducted thorough preconstruction activities, with Revery and Fast + Epp providing review on the shop drawings and construction plans. The use of timber Glulam and CLT members is estimated to save the build 1,255 tonnes CO2e.

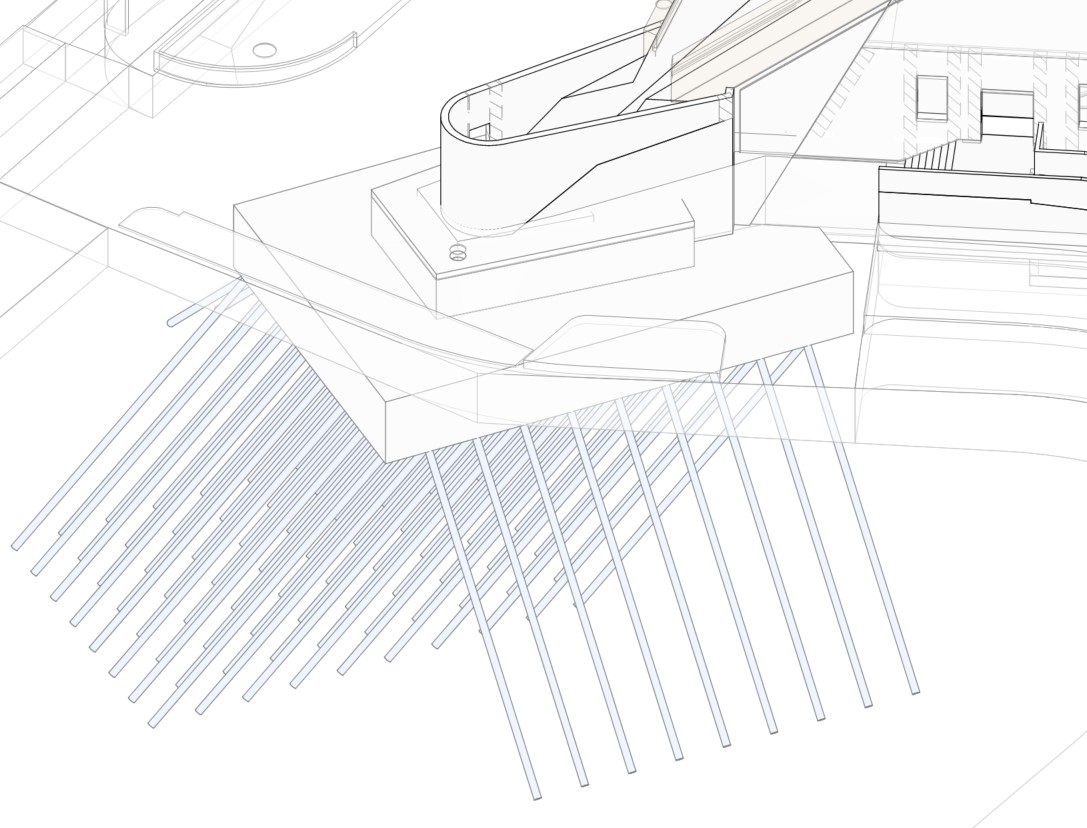

Foundation Revision:

Labour Effort: Savings, Carbon Impact: Medium, Cost: Savings

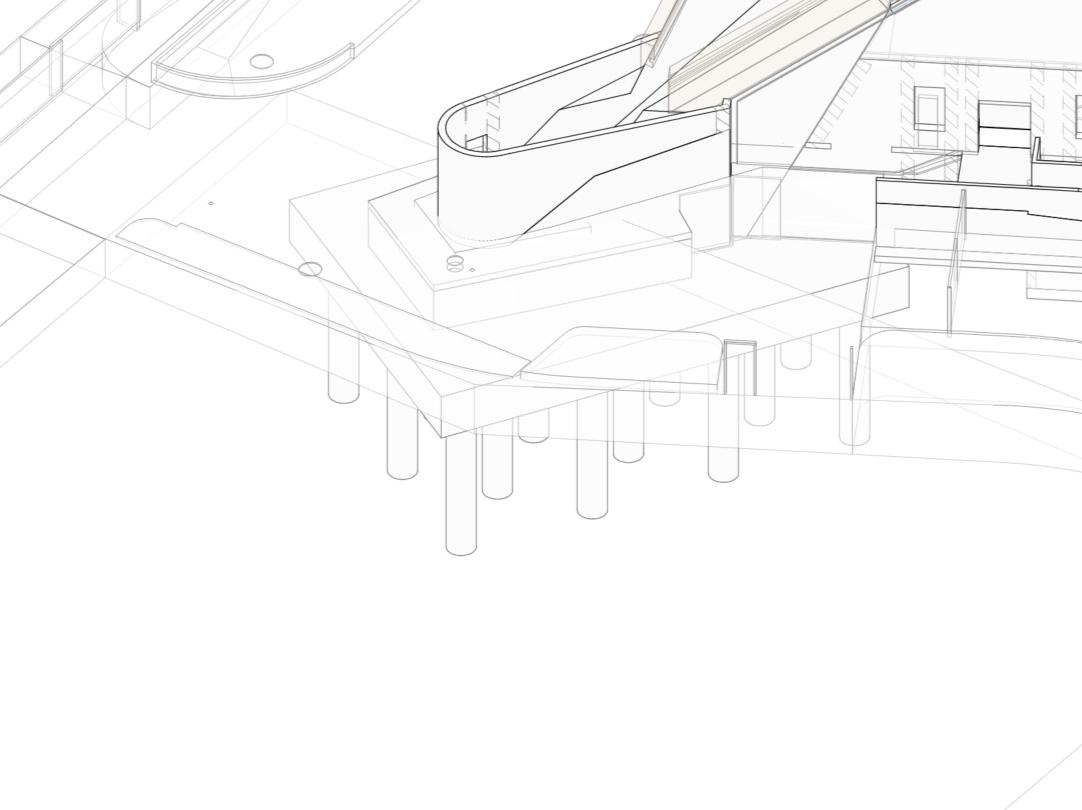

Foundation design is highly dependant on building geometry and location and can be a significant contributor to a building’s embodied carbon due to the quantity of material required. However, foundation design also offers one of the largest opportunities for carbon reduction – rarely is a foundation a component on the critical path of construction, and the relative simplicity of the design (fewer materials and considerations, such as aesthetics) can allow for carbon reduction to be prioritized. The foundation of the Amphitheatre was originally designed to be constructed using over 150 tonnes of steel micropiles. During preconstruction, EllisDon’s Ground Engineering experts reviewed the design and proposed an alternate solution using caissons, which would be much simpler to implement on-site, faster, and less costly. Despite the addition of concrete for the caissons, the net concrete volume used in the design diminished as the raft slabs were able to be reduced in thickness. The caisson design switch has resulted in an estimated carbon savings of 363 tonnes CO2e.

Fig 4a. Original micropile foundation design

Fig 4b. Revised caisson foundation design with reduced raft slab footprint and depth

Low Carbon Concrete:

Labour Effort: Low | Carbon Impact: Low | Cost: Neutral

While the steel and timber canopy is the central visual element of the Amphitheatre, a significant amount of concrete is used for the back-of-house building and the seating area. Fast + Epp set the expectation for low-carbon concrete in the project specifications and EllisDon analyzed the individual concrete elements for carbon reduction opportunity, balanced with other priorities such as placement methodology, schedule, and finish. These parameters were then incorporated into procurement, requiring that concrete suppliers provide global warming potentials (GWPs) that demonstrate that their proposed mixes meet the reduction targets, and provision of Type 3 Environmental Product Declarations (EPDs) following award. Elements in the substructure were identified as ideal candidates for ultra-low carbon concrete, due to the preferable properties of low carbon concrete in controlling heat in mass concrete. Other elements such as the buttresses require higher carbon self-consolidating concrete due to the shape of the elements and the placing methodology required. High early strength concrete has been restricted to applications where it is absolutely needed, such as the crane base, to accommodate the erection of the crane prior to the use of the adjacent fairgrounds for the Exhibition. Lafarge is supplying the majority of the concrete to the project, and their mixes are anticipated to reduce the carbon of the concrete by 45% relative to the BC Provincial Baseline at no cost or overall schedule premium.

Bonus: As-Built Tracking

Labour Effort: Low | Carbon Impact: Neutral | Cost: Neutral

EllisDon is tracking the construction and transportation emissions associated with the project. This actual data is being gathered and collated from a variety of sources; self-reported delivery information and fuel usage from subtrades, metering of fuel and power for site infrastructure, and machinery run time information pulled from smart camera technology. Following project completion this data will be used to update the project LCA, along with the actual carbon intensities (via product-specific EPDs, as available) and quantities of materials used in the construction. This exercise will help reconcile the difference between design estimates and real-world practices, allowing for more accurate planning and interventions in the future.