CLF BC Five Year Anniversary Celebrations

October 29, 2024

4th & MacDonald: Cost Savings and Carbon Reductions Through Optimized Structural Design

November 25, 2024

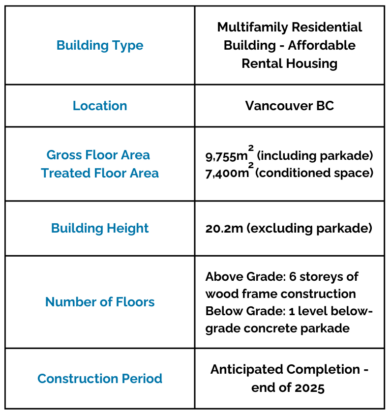

Project Description

Heather Place B (HPB) is an 87-unit affordable rental housing project located in Vancouver, British Columbia. It is a six-storey wood frame building, with a single level of unheated concrete parkade below grade. The project targets high levels of energy performance, meeting the levels in Path B of the Green Building Policy for Rezonings, and in line with BC Step Code - Step 4.

Project Overview

Project Team

Achieving ~29% Reduction in Embodied Carbon

The project team conducted a Whole Building Life Cycle Assessment (WBLCA) model and report as part of City of Vancouver’s Green Building Policy for Rezoning requirements. The report was completed according to the Green Building Policy for Rezoning – Process and Requirements document (July 14, 2019), with reference to the guidelines applicable at the time of the submission. Calculations included all envelope and structural elements; complete structural walls, floors, roofs, and excluded partitions; excavation, site development and building services. WBLCA was completed using Athena Impact Estimator for Buildings (version 5.4), the most current version at time of submission.

The Life Cycle Assessment results indicated the project's Global Warming Potential (GWP) of 281 kgCO2e/m2. When compared to City of Vancouver’s embodied carbon benchmark of 400 kg/CO2e/m2 (using the Absolute Path for establishing the benchmark), Heather Place B project achieves approximately 29% overall reduction in embodied carbon emissions.

The following case study looks at various approaches and design strategies that were utilized to achieve these reductions, at no cost premium.

Embodied Carbon Reduction Strategies

The most impactful design choices in relation to embodied carbon happen in early design. Early engagement with the entire project team (including Consultants and Client) is critical to establish reduction targets and embed this thinking into design philosophy across all disciplines.

The team divided the reduction strategies into two general categories - Large Scale and Small Scale:

- Large scale strategies are characterized as foundational, early conceptual design decisions that set the groundwork for the rest of the design.

- Small scale strategies focus on finetuning the design and material selection on the project.

Project specific design and embodied carbon reduction strategies at both of these scales are discussed in further detail below.

Large Scale Strategies

Above Grade Structural System

Selection of the above-grade structural system is usually the most impactful decision that the team can make, as structure typically accounts for the majority of embodied carbon on a project.

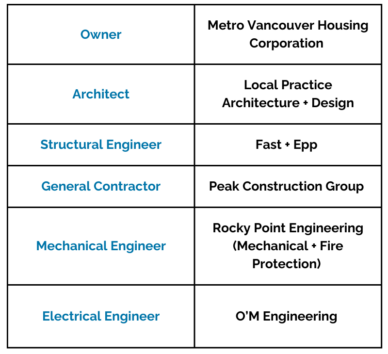

Heather Place B was originally designed as a fully concrete building. As concrete is known to be one of the largest contributors to a building's embodied carbon, the selection of an alternative structural system gives the largest opportunity for reduction. The Client made the decision to incorporate wood frame construction in earlier stages of design, which resulted in the most significant carbon reduction.

A comprehensive WBLCA model was not developed for the alternative concrete building design. However, the team compared the embodied carbon of Heather Place B (281 kgCO2e/m2) to the average intensity (350 kgCO2e/m2)1 of apartment building submissions received between 2017-2021 under City of Vancouver Rezoning – Embodied Carbon; these were predominantly concrete construction. From these figures, HPB is achieving approximately 20% reduction in overall embodied carbon emissions.1

Parkade Construction - Below-Grade Parkade Levels

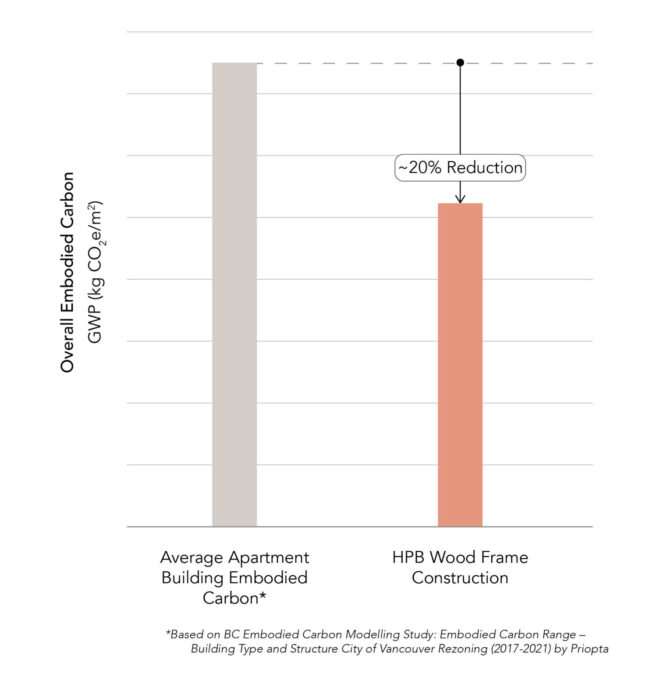

The material impacts of the parkade design include the actual quantity of concrete as well as site activity related to excavation typically not covered under WBLCA. It’s important to note that parkade design has a disproportionate weight on the overall WBLCA results. According to the City of Vancouver Embodied Carbon Guidelines for calculating embodied carbon, parkade floor area is excluded from the overall gross floor area (GFA) of a building for the purpose of GWP calculations. This means that when the overall GWP impact of the parkade is measured, it is not distributed across the additional area of the parkade.

While avoiding a below-grade parkade entirely would provide a drastic reduction in embodied carbon, this strategy is not always available to clients. Thus, careful consideration of limiting the number of below-grade storeys should occur in early stages of design to mitigate embodied carbon impacts of parkades.

HPB design was able to limit parking to one level of below grade parkade. Compared to an alternative design scenario, where HPB design would incorporate two levels of below-grade parkade, the single level achieved approximately 15% reduction in the overall GWP.

Parkade Construction - Below-Grade Water Management

Below-grade water management strategy should be carefully considered in relation to embodied carbon impacts. One approach to resisting uplift forces due to hydrostatic pressure from a high water table is to use self-weight of concrete; however, this approach can add a significant amount of material (concrete and reinforcing steel) to the overall parkade structure.

As an alternative approach, hydrostatic pressure can be relieved by alternative means, such as mechanical pump system, allowing significant reduction in the concrete structure.

On HPB, a fully tanked parkade with a concrete raft slab was considered in earlier stages of design. By changing the project’s approach for below-grade water management with a mechanical pump system, the team was able to reduce slab thickness to less than a third of the original design. This provided approximately 75% savings in GWP compared to the raft slab, which is around 35% reduction of the overall below-grade concrete impact.

Small Scale Strategies

Materials and Specifications – Low-Carbon Concrete

After foundational design decisions are made to minimize overall quantity of concrete used, concrete mix design can be considered to further reduce embodied carbon of below-grade structure.

On HPB project, the architecture team worked with the structural engineering team to establish GWP targets for the cast-in-place (CIP) concrete mixes for individual concrete elements such as walls, footings, suspended slab, slab-on-grade, and concrete topping. As each element has varying structural properties in terms of strength, exposure classification, and so on, each offers varying potentials for GWP reduction. When compared to the provincial baseline (Concrete BC Member Industry-Wide EPD for Ready-Mixed Concrete, released in 2022), HPB was able to achieve an overall estimated 15% reduction from concrete mix specification with the largest carbon reduction contributions coming from low-carbon concrete footings, suspended slab and beams, walls, and columns.

Materials and Specifications – Cladding Type

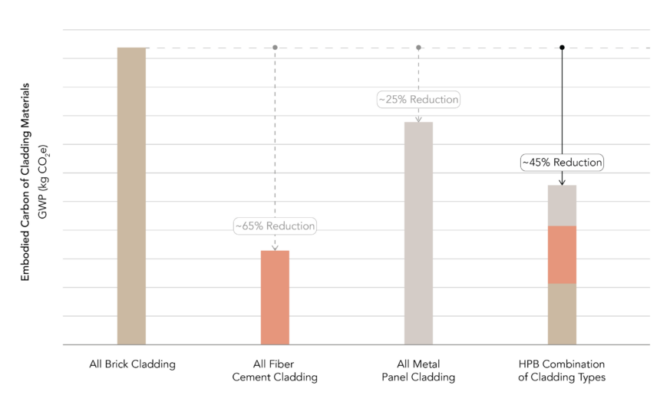

Cladding material selection provides an opportunity to reduce embodied carbon on a project, as different materials and their manufacturing processes range in embodied carbon emissions. When selecting cladding materials, it is important to consider durability, maintenance, cost (initial, as well as replacement), and aesthetics, balanced with embodied carbon values.

HPB used a combination of brick, fibre cement, and metal panel cladding. While brick could be preferred for its high durability, low maintenance, and desirable character and aesthetic, it has a disproportionately high embodied carbon impact. This is due the carbon-intensive manufacturing process, and the relative volume of the material used when compared to alternative cladding like fibre cement or metal. Fibre cement panel and steel panel cladding are used as alternative cladding options with lower embodied carbon emissions throughout the HPB project balance selective use of brick.

In a comparative analysis looking at various cladding options for the project, the team compared the impacts of cladding the entire building in brick, fibre cement or metal panels. Using a hybrid approach on HPB, with brick making up around 20% of the facade, the project achieved approximately 45% GWP reduction, relative to the all-brick cladding design.

Materials and Specifications - Fenestrations

Defining the fenestration products used on a project presents another opportunity to balance the energy performance of the project with the low embodied carbon targets. While window and exterior door selection is typically done on the basis of efficiency and building energy performance, embodied carbon should also be considered in the decision process.

In particular, the selection of frame type and number of panes for glazing (double vs triple pane units) can play a crucial role in performance and the energy model. The project team's high-level comparative study in Athena Impact Estimator showed that the embodied carbon reductions achieved by aluminum frame (highest embodied carbon), PVC frame (1% reduction), and fibreglass frame (10% reduction) window units provided relatively small savings compared to the reductions presented from glazing itself. Based on the comparative analysis, a switch from triple- to double-glazed window unit offers approximately 30% reduction in embodied carbon emissions.

For HPB, the energy model was completed early in the design process to understand various parameters and impacts of design decisions on the overall energy performance of the building. HPB energy model indicated that using double-glazed window and exterior door products can be accommodated when balanced with other design measures to achieve a high-performance building enclosure. As a result, the project was able to proceed with double-glazed units and achieve a balance between embodied carbon and operational energy.

Strategies presented in this case study are only a handful of approaches that were utilized on the HPB project. A much larger variety of strategies, both large and small scale, are available to the design teams if embodied carbon reduction is embedded as a foundational principle at the start of the project for the entire interdisciplinary team. The sooner the embodied carbon targets are considered the wider the range of strategies that remain available. For the Heather Place B Affordable Housing project presented here, the team was able to achieve approximately 29% reduction in embodied carbon compared to City of Vancouver’s embodied carbon Absolute Path benchmark at no cost premium.