The Marpole Community Centre

July 24, 2024

Trafalgar Project: High-Quality, Low-Carbon Homes for Every Generation

October 25, 2024

Introduction

This case study underscores the real and achievable potential for significant embodied carbon reductions in building projects, even within the typical constraints of cost, schedule, and supply.

Two projects illustrate this feasibility:

- Seymour Project: 9-Storey Residential Project in Vancouver (June 2023): As part of a City of Vancouver Case Study, the 1210 Seymour Street – Life Cycle Analysis (LCA) was conducted with the goal of achieving embodied carbon reductions without impacting cost or schedule. The LCA documented a 22% reduction in embodied carbon for the proposed measures with no negative impact on schedule or cost.

- Surrey Project: 11-Storey Confidential Commercial Project (July 2022): This project initially set out to target a 20% reduction in embodied carbon part of larger project Zero Carbon Building goals. Although the project was cancelled before a whole building life cycle assessment (wbLCA) could be completed, early-stage targeted analysis of concrete materials revealed significant opportunities for reducing embodied carbon.

Low Embodied Carbon Approach

The ZGF team approach all their projects with an understanding of the potential scale of impact they can achieve:

- Building Nothing / Re-use: Evaluating the potential for re-using existing structures wherever possible. This approach can significantly reduce the need for new materials, cutting down the overall carbon footprint from the outset. However, embodied carbon considerations should be weighed against potential trade-offs including the functionality of the spaces.

- Efficient Design: This includes several measures to optimize design and minimize the use of materials, such as:

- Utilizing geotechnical surveys to optimize foundation design and reduce the use of concrete.

- Minimizing transfer slabs by stacking units and reducing step-backs.

- Implementing Transport Demand Management (TDM) measures to reduce the number of parkade levels.

- Optimizing Material Selection: Evaluating specified materials and providing low-carbon options, including:

- Low-carbon insulation.

- Electric Arc Furnace steel.

- Low-embodied-carbon concrete mix designs.

ZGF is developing similar approaches for Interior, Site, and Mechanical Embodied Carbon considerations.

Scale of impact against typical project schedule with embodied carbon decisions

Seymour Project - 9-Storey Residential Building

Description

1210 Seymour Street is located in the center of downtown Vancouver, BC. Scheduled for completion in November 2026, it will provide 112 efficient, affordable rental homes in a mix of studio, one-bedroom, and family units.

Credit: ZGF Architects

Project Overview

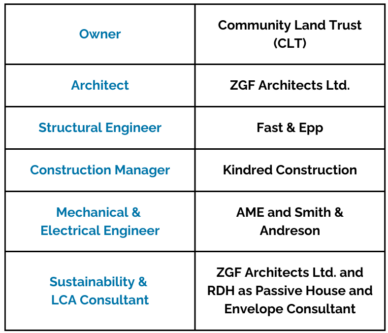

Project Team

Achieving a 22% Reduction in Embodied Carbon

In 2023, the project was selected as a case study to evaluate the City of Vancouver's Embodied Carbon Requirements and demonstrate how they can be met at no additional cost. The estimated embodied GHG emissions are 342 kgCO2eq./m² for the structure and envelope, assuming a 60-year building lifespan. The OneClick whole-building life cycle analysis revealed a 22% reduction in embodied carbon compared to the baseline.

Life Cycle Assessment Results

To meet the City of Vancouver's Embodied Carbon Requirements (v.02), the project team conducted an LCA analysis to quantify the GHG or embodied carbon emissions of the building materials. The LCA, conducted in 2023 using OneClick (v4.0.4 2022), is based on quantity take-offs generated from the project drawings. The study quantified the building structure and envelope, which constitute the majority of the building materials, and its scope defined as cradle-to-grave. This encompassed production, construction, use (maintenance and replacement), and end-of-life (deconstruction, waste processing, and disposal) stages.

Assuming a service life of 60 years for the building, the LCA analysis estimated the total embodied carbon emissions of the structure and envelope at approximately 3,013,464 kgCO2eq, or 342 kgCO2eq/m² for the total gross area of 8,800 m².

Embodied Carbon Reduction Strategies

The primary strategies for meeting and exceeding the Vancouver Building By-law (VBBL) Embodied Carbon Regulations were as follows:

- Reducing the Levels of Parkade: Cutting the number of parkade levels reduced the volume of concrete used in the project and resulted in an 8% reduction in overall embodied carbon. The team implemented Transport Demand Management (TDM) measures to decrease parking requirements and increase bike- and car-sharing options. They also relocated the mechanical plant from the parkade to the roof.

- Optimizing Structural Design: Optimizing the design and stacking the units led to a 3.2% reduction in overall embodied carbon by minimizing the need for transfer slabs.

Parkade reduction and Structural Optimization (reducing transfer slabs)

- Specifying Low-Embodied-Carbon Insulation Products: This resulted in a 3.8% reduction in the overall embodied carbon of the project.

- Specifying Low-Embodied-Carbon Concrete Mix Designs: This contributed to a 7.0% reduction in the overall embodied carbon of the project.

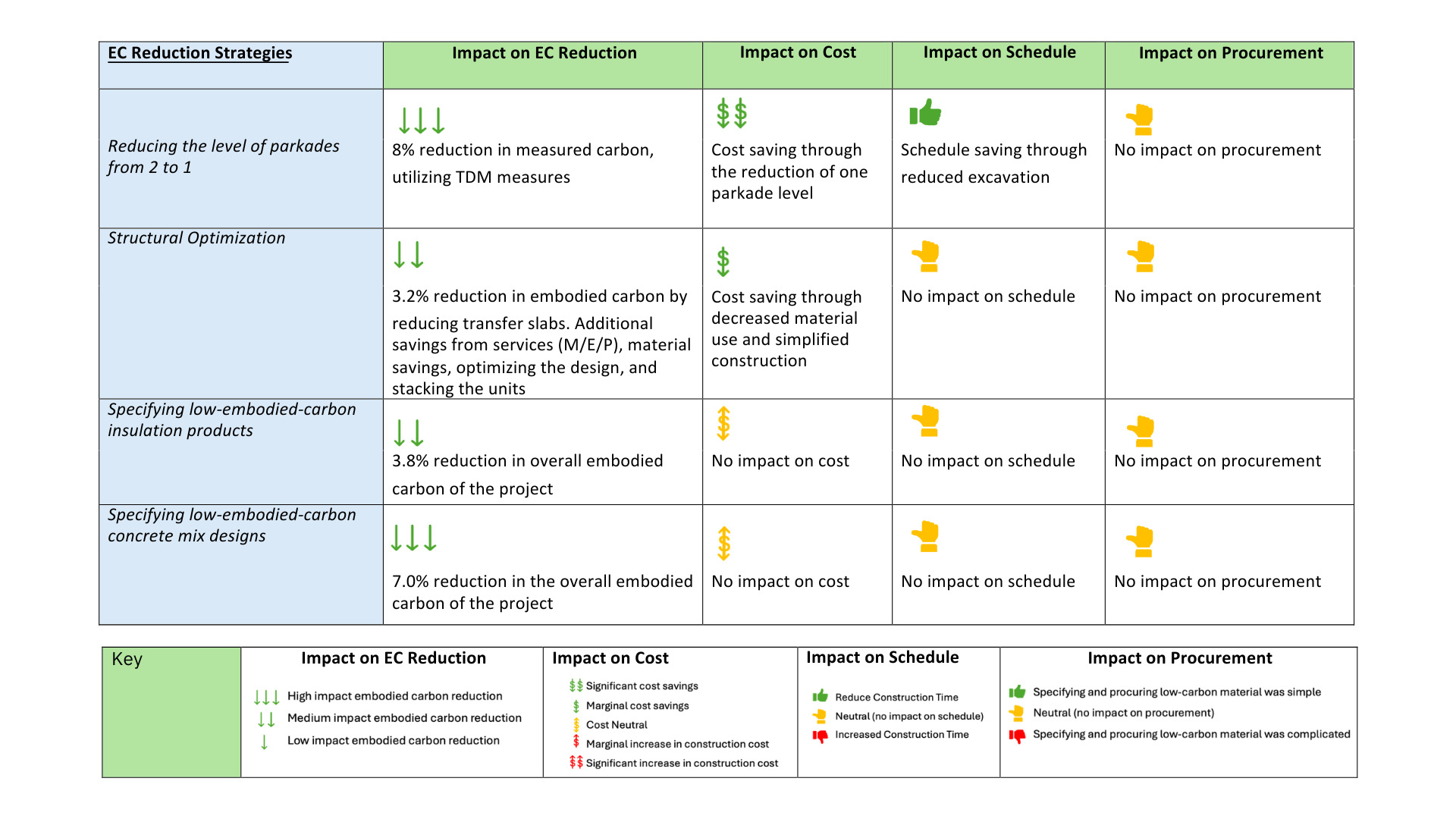

Summary

The following table summarizes the embodied carbon strategies for the Seymour project developed to avoid increased cost or negative impact on schedule.

Surrey Project - 11-Storey Commercial Building

Description

This confidential 11-storey commercial project in Surrey was cancelled as a result of COVID-19. The office tower was in the design development phase, envisioning a 20% reduction in embodied carbon through design and material optimization.

Project Overview

Project Team

Minimum 14.1% Reduction in Embodied Carbon for Concrete

The Surrey project aimed to achieve a 20% reduction in embodied carbon as part of the project’s larger zero carbon building goals. The estimated embodied carbon of the concrete elements totaled to 195.5 kgCO2eq./m², and the EC3 analysis conducted in July 2022 indicated a 14.1% reduction in concrete's embodied carbon. Further reductions in embodied carbon did not occur as the project was cancelled.

Life Cycle Assessment Results

The project team conducted a directional embodied carbon analysis on concrete during the early design development stages. The LCA was performed using EC3, based on quantity take-offs generated from the project drawings. The scope of the study was cradle-to-gate, covering stages A1-A3 only.

It should be noted that the directional embodied carbon analysis would have been combined with further embodied carbon savings from steel and insulation and documented through a full LCA. The directional analysis was used as a tool to rapidly iterate through design options and optimize concrete materials.

Embodied Carbon Reduction Strategies

Before its cancellation, the project evaluated savings from design efficiency and concrete mix design optimization. The team also planned to investigate further savings from low-embodied-carbon insulation and rebar as part of the strategy to achieve a 20% reduction in embodied carbon.

The main strategies developed were as follows:

- Reducing the Floor-to-Floor Height: This aimed to reduce the overall volume of material used in the project. Preliminary results indicated an approximate 1% saving in concrete embodied carbon.

- Reducing the Number of Elevators: This not only optimized the core design but also reduced the need for structural transfer slabs. Preliminary results indicated an approximate 1% saving in concrete embodied carbon.

- Low-Embodied-Carbon Concrete Mix Design: The team investigated potential savings through optimizing the concrete mix design. The concrete supplier provided three options for carbon savings and associated cost premiums:

- Option 1: A 12.1% reduction compared to the 810.CRMCA_EPD_BC.pdf (concretebc.ca), with no additional cost to the project.

- Options 2 and 3: Concrete mix designs offering larger carbon reduction savings compared to the BC Industry Average EPD, though with increased associated costs.

Project 2 Concrete Performance Mix Design requirements and associated Global Warming Potential of mix designs and savings against BC Concrete Industry Average EPD. Baseline Column is taken from concretebc.ca and Option 1 (NO ADDITIONAL COST), Option 2 and 3 were provided by local concrete supplier.

Summary

The following table summarizes the embodied carbon strategies for concrete alone; further reductions would have been sought through steel and insulation embodied carbon savings.