Calling Ministries Project: High-Quality, Low-Carbon Homes for Every Generation

Cost-Neutral Embodied Carbon Reduction Strategies for Residential and Commercial Buildings

October 7, 2024

CLF BC Five Year Anniversary Celebrations

October 29, 2024

Introduction

The Calling Ministries project (CM) provides high-quality affordable accommodation for seniors and visiting students on the Calling Ministries site. This innovative development will replace two existing buildings that have deteriorated beyond repair with an environmentally sustainable facility. Within the same site, two other buildings have been approved by the City of Vancouver for full envelope retrofit renovations that will match the same aesthetics of the proposed building. The new building will not only offer modern, comfortable, and affordable subsidized living spaces tailored to the needs of seniors but also incorporate sustainable design principles to minimize environmental impact. With a focus on comfort, health and environmental responsibility, this project represents a significant step forward in enhancing the quality of life for our senior community while promoting green building practices.

Project Description

The CM project will provide a wide range of unit sizes, including accessible studio units and family sabbatical units as provided in the existing buildings. A large south-facing amenity room looks out onto the rear gardens and has an extended roof overhang for solar-shading. The proposed outdoor amenity will feature beautifully landscaped gardens with accessible walking paths, a playground, raised community gardens, and cozy seating areas perfect for relaxation and socializing. The new accommodation also includes a counselling suite in addition to minimal parking (three spaces) located at grade and adjacent to the building.

The intent of the new building’s aesthetic is to respond to and respect the existing buildings on the site, which feature off-white stucco and siding, and pitched gable-end roofs. The material palette is the same as the two buildings being upgraded and consists of a mix of wood-effect composite cladding, stucco, and dark gray cladding panels to create a timeless aesthetic. The materials have been carefully chosen for quality, low maintenance, and longevity. The facades are broken down to a more domestic scale through the contrasting colours, materials and roof articulation.

The main entrance is highlighted with the same wood-effect cladding as on the adjacent proposed renovations. The exterior exit stair reflects those on the adjacent buildings and assists with building energy efficiency.

Model Visualization: Front Elevation

Model Visualization: Rear Elevation

Project Overview

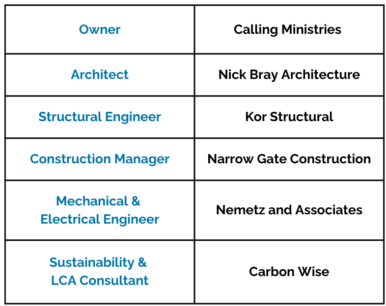

Project Team

Achieving a 36.72% Reduction in Embodied Carbon

Life Cycle Assessment Results

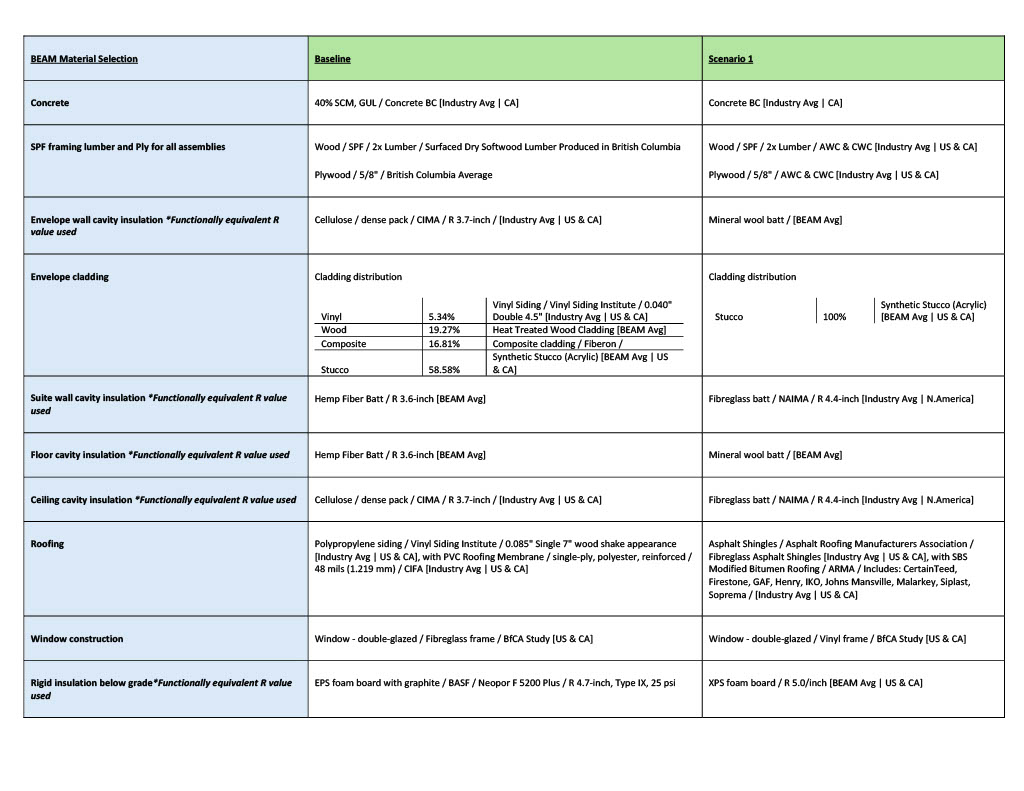

LCA (A1-A3) Methodology

Modeling of material impacts for this building was conducted using the BEAM 1.1 tool focusing on the cradle-to-gate, or A1-3, carbon emissions of those materials. Building geometry was used to define material quantities using the tools and database provided by the BEAM tool. Material volume calculations were supplemented with additional calculations to determine the appropriate percentages necessary to make inputs more accurate. Building geometry was taken from working plans provided by NBA using markups in Bluebeam PDF software.

Initially, a preliminary model was created using the assemblies described in the plans. Material selections were made with the intention of demonstrating best practices and lowest impacting materials reasonably available. Details regarding material choices in all scenarios are available in the BEAM material review document and are summarized here.

After establishing the current design, a typical ‘baseline’ construction scenario was created using material selections more typical in residential construction. These focused on reverting concrete mixes to provincial averages, timber to national averages, and replacing hemp and cellulose insulation with fibreglass insulation. All insulation in walls responsible for fire separations was input as mineral wool in all scenarios.

Windows were changed from fibreglass to vinyl construction with similar glazing, resulting in an increase in carbon emissions for that building element. However, it should be noted that fibreglass windows are likely to maintain performance longer and demonstrate longer service life because they are highly durable and stable. They often last up to 50 years, significantly longer than vinyl or wood windows, which typically last 15 to 30 years, resulting in lower maintenance and replacement costs. The costs and embodied carbon impacts of those replacements are not considered here as the system boundary of this evaluation is restricted to A1-A3.

Lastly, the cladding material was changed, as were the roof surface materials.

-

Notable substitutions and interpretations

The BEAM tool allows the easy input of three wall types. Envelope walls represent walls W1 and W2 as noted on the plans. Party walls represent walls P1, P2, P5, and P6. Interior suite walls represent wall P7. Each assembly within these categories contains essentially the same components but in different proportions. For example, some walls contain additional layers of drywall for fire separation, whereas others are double-stud variations on similar single-stud walls.

To accommodate these differences total wall areas were determined for each assembly noted on the plans. Next, the layers of each component were isolated and a material equivalency (eq) factor was determined for each layer. In other words, if two layers of drywall are present for a given wall area then its material eq factor will be 2. These could then be used to calculate the total area for each layer and converted to a percentage that would reflect the same material volume in a single layer. For example, if 50% of a wall area entered into BEAM had two layers of drywall and the remainder had only one, then the framing could be input for the total area at 100%, and the drywall could be entered for the same area but at 150% to capture the total impacts of that assembly. This was done as needed to harmonize all assemblies.

Because there is no EPD data for the vinyl roof tile that is listed in the baseline design, a best equivalent product category EPD was selected as a substitute. The EPD published for Industry Averaged Polypropylene Siding (0.085” Single 7” Cedar Shake) was used. Its material category, lifespan, weight, and other known characteristics represent the most functionally equivalent known material impacts.

At this stage of design, structural engineering has not yet been completed. As such, minimal assumptions were made regarding heavy supports (i.e. columns and beams). An assumed 60% framing density was calculated for the elevator and interior stair walls, and typical heavy timber dimensions were used to estimate the structure used to support the exterior stair. These inputs remain consistent in both scenarios, but likely under-represent the total amount of heavy framing that will be used. However, the design lends itself to minimal structural support beyond the envelope and interior shear wall constructions.

The facility of the BEAM tool to calculate “garage” elements separately was used to calculate the impacts of the exterior staircase in this analysis, and so those materials are calculated separately from those contained within the heated envelope. This includes the structure, floors, walls, and ceiling of the stairs. Treads are not considered in any scenario.

Embodied Carbon Reduction Strategies

With operational emissions minimized through an all-electric design—featuring heat pumps, HRV systems, and no reliance on natural gas—the focus on embodied emissions becomes even more critical.

As the building’s energy use becomes cleaner, the proportion of carbon emissions stemming from the materials and construction process gains greater significance. By conducting a Life Cycle Assessment, the team incorporated several strategies. These included optimizing structural efficiency using low-carbon materials where feasible and minimizing waste during the construction of modular and prefabricated walls. These not only lower the overall carbon footprint but also often result in cost savings through reduced material usage and more efficient construction processes.

Additionally, prioritizing embodied carbon reduction encouraged innovative design solutions, such as relocating the staircase outside, which decreases the need for internal space and reduces the total floor area. Addressing embodied carbon is therefore essential to ensure a holistic approach to sustainability that covers the full life cycle of the building.

The key strategies include the following:

-

No parking/basement and use of low-carbon concrete on foundation

Proposing only three parking spaces at street level decreases the amount of concrete and steel required for parking structures. Based on past projects, this could result in an estimated savings of 250 tons of CO2e. While parking was not factored into any of the scenarios in this case study, it is still worth highlighting as a significant potential contribution to reducing the overall carbon footprint. Parking areas often involve significant material use and energy-intensive construction processes, contributing significantly to embodied carbon. By limiting the number of parking spaces, the overall demand for these high-carbon materials is reduced. Plenty of bike storage has been implemented to balance the lack of parking.

Where concrete was necessary for the design, the team opted for a low-carbon alternative that incorporates 40% supplementary cementitious materials (SCM).

-

Simple wall and roof assemblies

Simple wall and roof assemblies reduce embodied emissions on this project by minimizing material use and waste, streamlining production, and facilitating easier transport and handling. Additionally, their straightforward design often leads to quicker and more efficient construction, further reducing emissions associated with labour and machinery. Simplified assemblies also tend to be more durable and easier to disassemble to allow for future upcycling or reuse, supporting a more sustainable end-of-life scenario for the building materials. If a whole-building life cycle assessment (WB-LCA) was completed for this project, such that the embodied carbon of the end-of-life stages (i.e., C1-C4), and the beyond-building life (i.e., life cycle stage D) were measured, it is reasonable to assume that even greater embodied carbon reductions could be realized on this project.

Switching from a standard 2x8 mineral wool batt assembly using the industry average to a 2x8 wall filled with dense-pack cellulose sourced from local wood suppliers can reduce the project's carbon impact from 11,152 kgCO2e to -4,309 kgCO2e. This transforms the wall assembly into a carbon-storing solution. Likewise, replacing a standard TJI roof of fibreglass batts with a dense-packed cellulose roof using locally sourced plywood reduces the project's carbon footprint from 17,734 kgCO2e to 4,368 kgCO2e.

It's important to mention that the vinyl roof tile chosen for this project was approximated using a similar option from the database (refer to the methodology section). While it shows a higher upfront impact, the manufacturer offers a warranty of up to 50 years compared to the 15-to-20-year replacement cycle typical for asphalt shingles. Due to limitations of the BEAM software, a full life cycle comparison could not be conducted for this material.

-

Small suites, efficient spaces

Simpler unit designs (all units are rectangular) often involve standard components that are easier and more energy-efficient to produce, transport, and assemble. By reducing complexity and focusing on efficient use of space, small and practical unit layouts contribute to a lower embodied carbon footprint while maintaining functionality and comfort. The proposed flex residential units feature a versatile design with a bedroom that can be seamlessly shared with an adjacent unit, enhancing adaptability and functionality. The core concept revolves around a modular bedroom space that can be opened or closed to connect with the neighbouring unit based on need. While it's difficult to quantify these savings in the LCA, it's important to consider the potential benefits of reducing material use altogether; the savings come from what is not included in the first place.

-

Low form-factor massing (rectangular design)

The building's simple shape maximizes available interior space relative to the area of its envelope and so requires fewer materials compared to a complex, irregular design. Fewer materials mean less extraction, processing, and transportation, which effectively reduces embodied emissions and supports better operational efficiency.

Although difficult to quantify specifically, simple form factors lend themselves to efficient construction timelines and easy access during construction. They can encourage engineers to optimize material considerations in structural design by allowing flexibility when considering the distribution of load over required spans. They facilitate efficiently designed HVAC systems that distribute air more evenly and support lower operational energy consumption while also reducing required ducting equipment.

-

One interior, one exterior staircase

One strategy used to simplify the building's design entailed relocating one of the stairs to the exterior of the building, effectively reducing the need to free internal space for residential use and simplifying structural and mechanical design.

An exterior staircase can reduce the area of internal walls and floors required for a similar internal staircase. This, in turn, decreases the total amount of envelope materials (such as drywall, insulation, and finishing materials) needed for the building. The exterior staircase also simplifies the interior layout, reducing complexity in the construction of internal partitions.

-

Composite cladding and stucco

One of the selected cladding materials is composite cladding, which is often made from recycled or low-carbon-content components. This typically requires fewer resources and energy to produce and install compared to conventional options. The other system selected is stucco (industry average option in BEAM), which is durable and weatherproof in a single, streamlined system that reduces the need for additional layers and materials. The materials used in stucco—sand, cement, and lime—are typically sourced locally. This reduces transportation emissions and supports local economies. The proposed long-lasting materials will extend the lifespan of the building envelope, minimizing the need for frequent replacements and repairs. Foam products are not used above grade.

-

Cellulose and hemp batt insulation

The use of cellulose and hemp batt insulations will help minimize embodied carbon in the building by incorporating renewable, low-carbon materials. Cellulose, which will be used in exterior wall and roof assemblies, is a cost-effective and sustainable choice. Not only does it reduce the carbon footprint of these assemblies, but it also supports a circular economy by utilizing recycled materials. Hemp batt insulation will be applied in non-fire-rated interior walls, such as suite divisions, offering another rapidly renewable option that requires less energy and fewer resources to produce than traditional insulation. This approach, providing both environmental and financial benefits, might be one of the simplest solutions to implement to reduce embodied carbon.

-

GPS insulation under slab reduced (No foam products over slab)

By optimizing and reducing the thickness and application of below-slab insulation, the overall embodied carbon will be reduced. Reducing reliance on excessive insulation can lower the total material requirements, further decreasing the carbon footprint associated with the building's construction. In this case, XPS rigid foam insulation was used for comparison; by minimizing the insulation where it's not needed, we can significantly reduce both material usage and environmental impact without compromising the energy performance and thermal breaks.

-

Fibreglass windows

The production of fibreglass involves melting glass and combining it with resins at high temperatures, which is an energy-intensive process that results in higher initial carbon emissions. However, despite their higher upfront carbon impact compared to vinyl or wood windows, fibreglass windows offer a balanced, resilient, and long-term choice. Their exceptional durability, energy efficiency, and low maintenance over a lifespan of up to 50 years is significantly longer than the 15-20 years typical for vinyl or wood. Their durability and low maintenance result in a longer lifespan, reducing the need for frequent replacements or repairs. While the initial embodied carbon may be higher, a full cradle-to-grave whole-building Life Cycle Assessment might justify the extra investment compared to vinyl or wood.

The decision to use double-pane windows over triple-pane was a conscious choice aimed at reducing embodied carbon, as double-pane windows typically require fewer materials and resources during production. Double-pane windows often result in cost savings, both in terms of upfront purchase and installation, while still providing the required thermal performance for energy efficiency.

Appendix